Eliminating Chills with SOLUCORE® Plus J23™ – A Case Study

Introduction

Chills are a useful aspect of pattern making, especially when working with patterns with thick sections, where they prevent sinkage.

However, there are also a number of disadvantages to using them:

- The use of chills increases the time of each pattern to produce

- The chills require additional resources to produce them

- The use of chills is time consuming and subject to various scrap issues

So by removing the need to use chills in your pattern you can:

- Reduce process times

- Reduce costs and overheads

- Simplify set-up

- Use a single wax blend for the pattern.

This case study shows how the need for chills in a pattern making can be removed, by changing your pattern wax.

The Wax

Solucore® Plus J23™ is an innovative soluble wax product which is has had some amazing success worldwide in foundries. Many customers have found the wax extremely easy to use and the following benefits:

- Excellent injectability – no crazing on the surface

- Fastest dissolution rate in the market*

- Less shrink and sink than other soluble waxes – eliminates the need for chills

- Excellent life of wax presses – less seal changes than conventional soluble wax

*during customer trials

Easy to inject

The novel Solucore J23 formulation has been optimised for ease of use. The wax can be easily injected with no issues with injection crazing or sink. The novel formulation ensures the injection of the wax is optimised for both thick and thin parts.

Elimination of chills

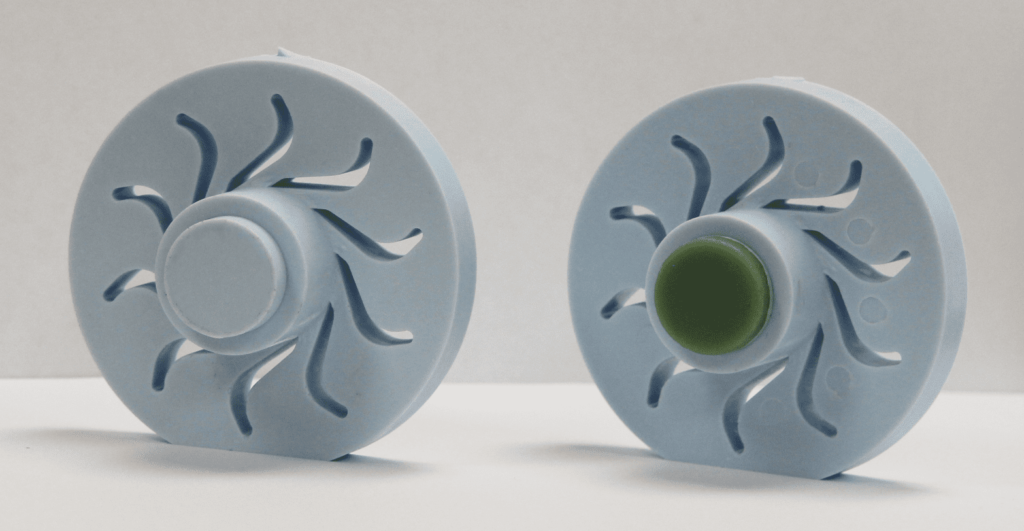

REMET UK was tasked with injecting the part shown below by Lost Wax Developments Ltd. The customer had issues with sink in the thick core area of the venture part, which needed a chill. Figure 1 shows the part geometry, the thick centre section had excess sink due to the bulk volume during cooling.

Figure 1

Following some initial optimisation of flow and temperature parameters, the chill was removed to assess sink in the area with Solucore Plus J23. Following 24 hours of cooling, a straight edge was used to measure the sink in the area. There was no increase in sink in the area with and without chills.

The removal of chills allowed LWD to improve efficiency at injection, reduced tool assembly time and dimensional changes within the part. To quote Alan Willetts of Lost Wax Development, “It looks like a standard pattern wax rather than a soluble wax!”. The customer also commented the dissolution was also much quicker in production.

Fast dissolution rate

The solucore J23 has been specifically optimised for fast dissolution time also to improve efficiencies. Dissolution times of up to 60% have been seen when compared to other soluble waxes on the market!

Less harsh on wax injection machines

REMET UK have been injecting Solucore J23 within their facility for over 18 months now without the need to change the seals on the wax press. This is a step change from the harsh soluble waxes which can reduce the life of the seals in the press and cause significant downtime and maintenance. Parts have been made on a weekly basis with this machine without issue or breakdown due to injecting soluble waxes.

Conclusion

Solucore J23 is a step change from the current soluble waxes within the market. The reaction from customers all over the world has been extremely positive to the surface finish and dissolution rate.

Solucore J23 has the ability to eliminate the need for chills without causing sink or cavitation issues. Contact your local REMET representative today to discuss optimising your process with REMET Solucore J23 wax.

With Thanks

Our thanks go to Lost Wax Development and Newby Foundries Group

More Information

For more information about how Solucore Plus J23 could benefit your production or on any of our other products please contact you local REMET representative.

< Back to case studies