Factors Effecting Slurry Rheology

Purpose of Slurry Rheology Control

Today, Foundrymen are interested in controlling casting quality. This includes the control of surface finish, internal shrink and metal grain size. Shell and metal controls work synergistically to create conditions that produce a quality product on a consistent basis. This paper will address factors that affect shell uniformity – namely slurry rheology control.

Definitions

Rheology is the behaviour of matter in the fluid state. Viscosity is one tool used to measure and control rheology. Viscosity is a measure of the internal friction of a slurry. It measures and predicts how the slurry will flow and to some extent, how much will remain on the wax assembly. The slurry remaining on the assembly after drain is the foundation for the ceramic mold or shell. The second important slurry property is thixotropy. Thixotropy defines how the slurry flows under changing shear conditions. Practically, as slurry drains and levels, it forms a film of defined thickness. A thixotropic slurry becomes more viscous as the shear decreases, leaving a thick film. Plate weight is one method used to indirectly measure thixotropy and film thickness. Plate weight measurement is defined in the ICI Test Procedure 720-79.

Measuring and controlling plate weight and viscosity characteristics of a slurry has become more important with the use of robots in shell production. Robots repeat the same motions time after time and cannot make adjustments for changes in slurry rheology. For this reason, slurry control takes on added significance in shell production.

Factors Affecting Slurry Rheology

All materials used to build a slurry affect rheology. This includes refractories, binders and additive packages. Refractories have the greatest influence on the system behaviour because it is usually the largest component of the system. Common refractories used in face coat slurries are:

- Fused Silica

- Zircon

- Aluminosilicates

- Alumina

- Zirconia

- Yttria

Refractory properties, i.e. density, morphology (particle shape), particle size and distribution all influence slurry rheology. Table 1 compares the density and shapes of refractories commonly used in precision casting slurry applications.

Table 1 Density of Precision Casting Refractories

| Refractory | Mineral density |

| Fused silica | 2.2 |

| Zircon | 4.5 |

| Tab Alumina | 3.96 |

| Fused Alumina | 3.96 |

| Aluminosilicate | 2.64 – 2.88 |

| FUSED MULLITE | 3.14 |

| ZIRCONIA | 5.68 – 6.10 |

| YTTRIA | 4.84 |

From experience, it is clear that fused silica prime slurries drain, and level slowly compared to an all zircon slurry. The drain and levelling difference between fused silica and zircon slurries is attributed to the refractory density and shape. The pull of gravity causes the slurry to drain from the pattern faster for zircon than fused silica, while the rounded shape allows for easier flow of the particles over each other within the slurry.

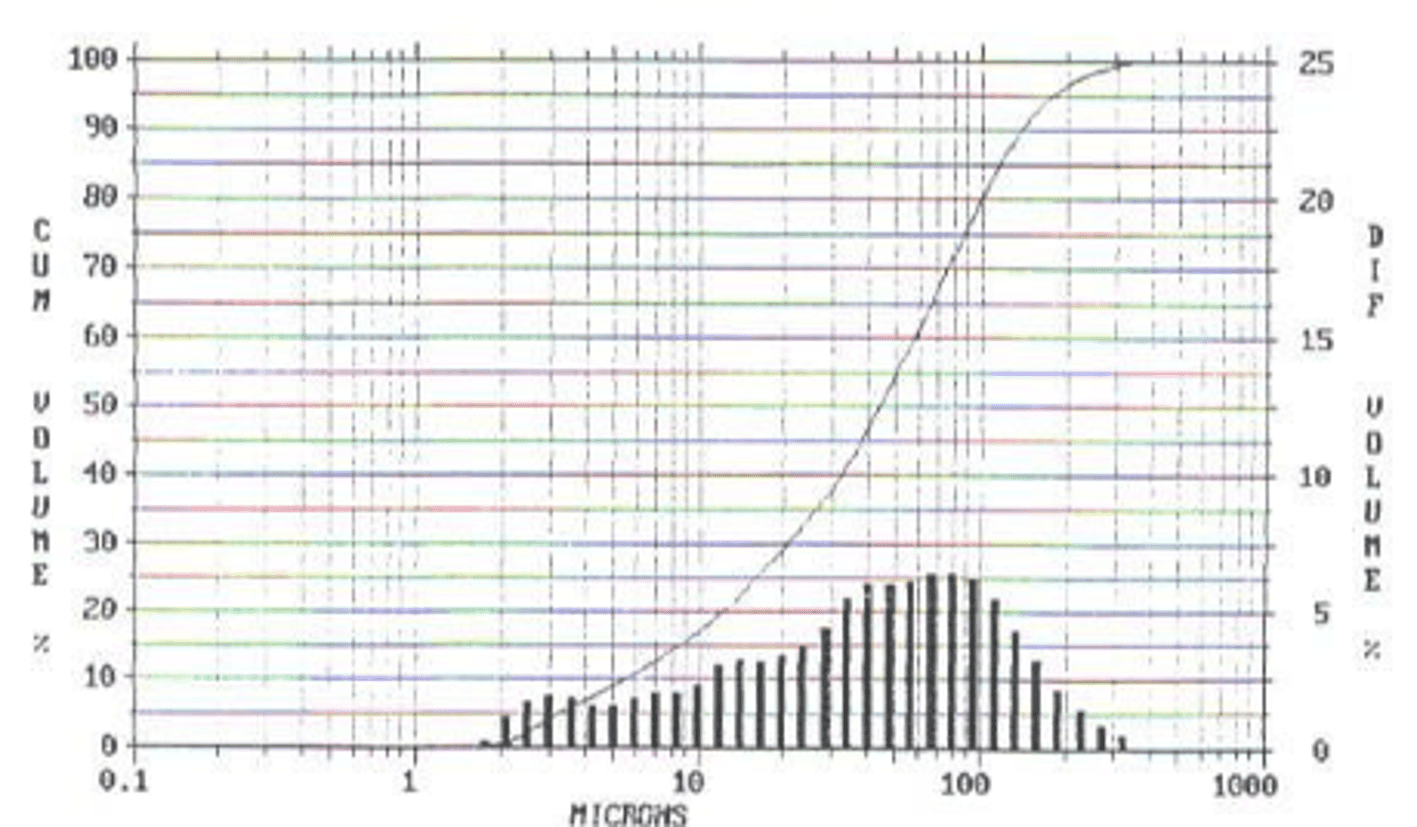

After the pattern has drained, a film of slurry remains. The film thickness is defined by the refractory particle size and distribution as well as morphology. Large, well distributed particle size will result in a thicker slurry deposition. These types of Wide Distribution refractories are available from all suppliers in the PIC Industry. More on particle size distribution and measurement is within our other article here (https://www.remet.com/us/insights/refractory-insight-part-2-testing/)

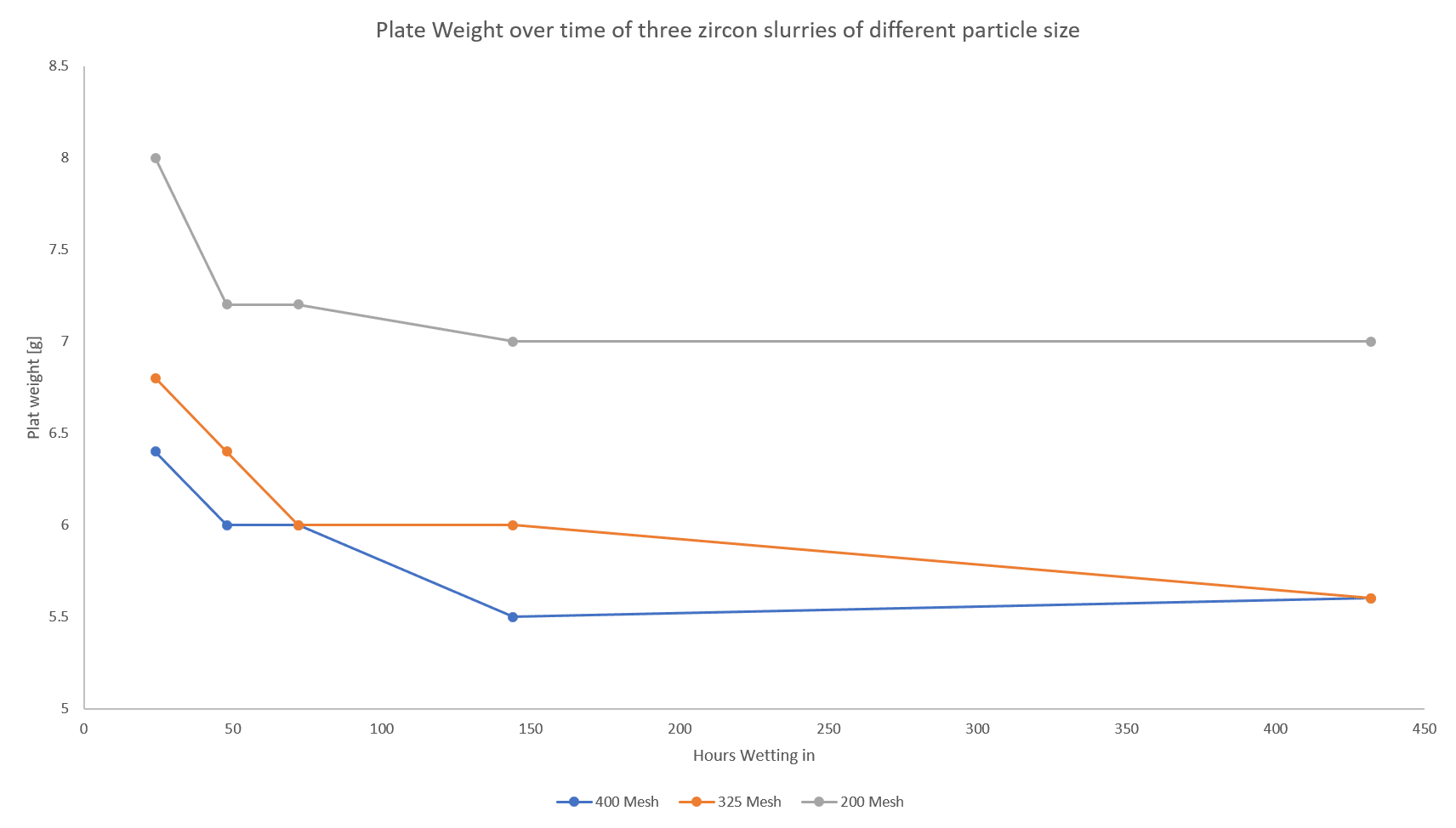

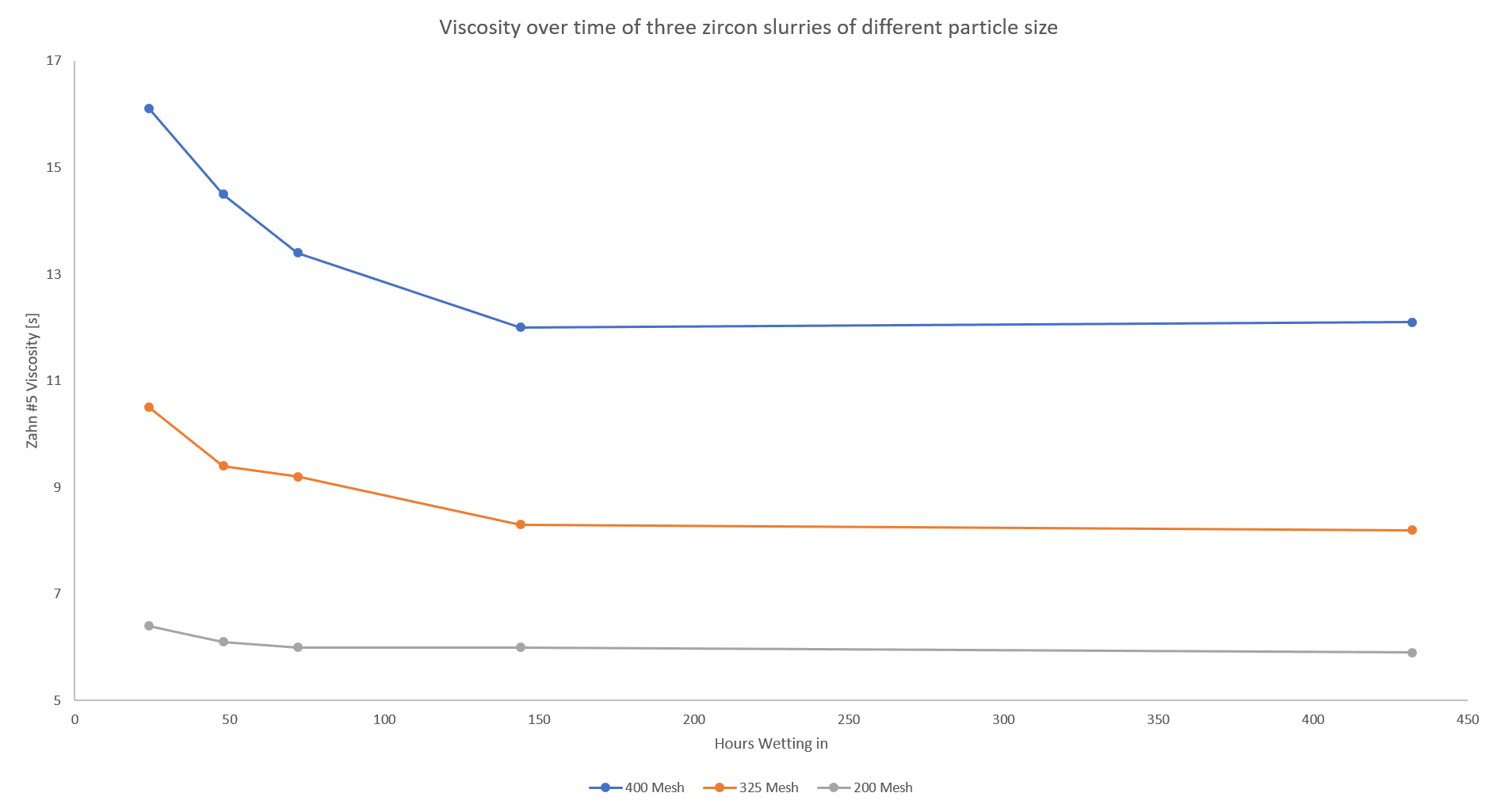

You will recall that earlier I described a test, plate weight, for measuring film thickness. This test when used in conjunction with viscosity is an indirect measure of refractory particle size and distribution. Several slurries were prepared within the REMET lab to show the effect of particle size and refractory (zircon and fused silica) on slurry rheology. Table 2 shows the standard formulation for all three zircon slurries. The variable is the grind of zircon flour used in the slurry, 400, 200 and 325 mesh respectively.

Table 2 Zircon Slurries Formula

| Material | Quantity |

| Colloidal silica | 900 g |

| Water | 100 g |

| Surfactant | 2.1 ml |

| Antifoam | 1.0 ml |

| Zircon flour | 4000 g |

| Solids contents | 85% |

Figure 1 compares the viscosity (sec) and plate weight (g) for each slurry. You will note from the viscosity data that the -200 mesh zircon flour wets in quickly compared to the other two flours. Both 400 and 325 mesh zircon are not completely wetted until 144 hours of mixing. The mixing method used in these studies were the same, i.e. ingredients were placed in a jar mill and rotated. High shear mixing would shorten the time required to completely wet in the slurry. Also worth note is the plate weight increases as refractory particle size increases – even though the corresponding viscosity drops.

| Figure 1 (a) Plate weight and (b) viscosity measurements over time versus different zircon PSD | |

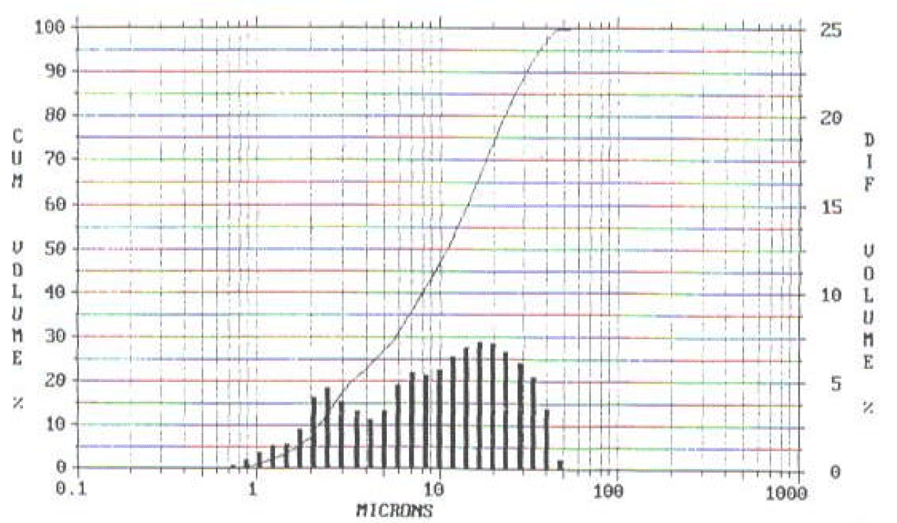

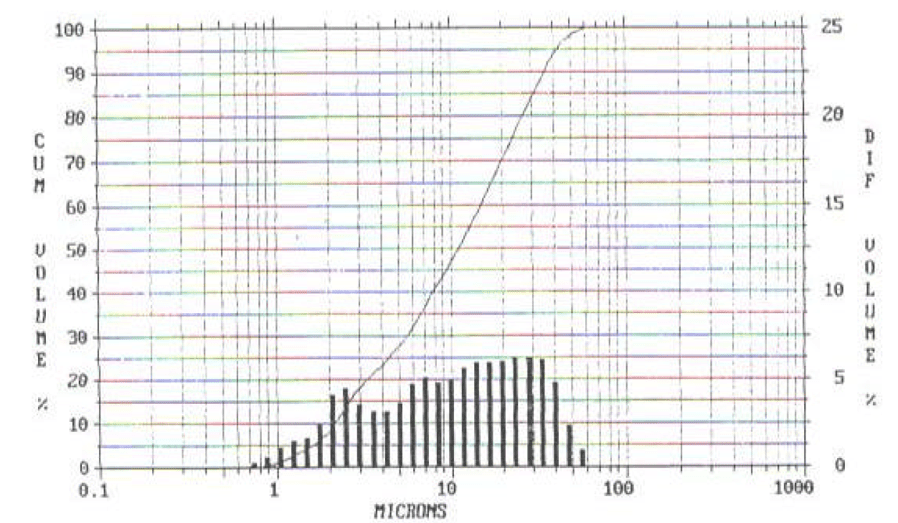

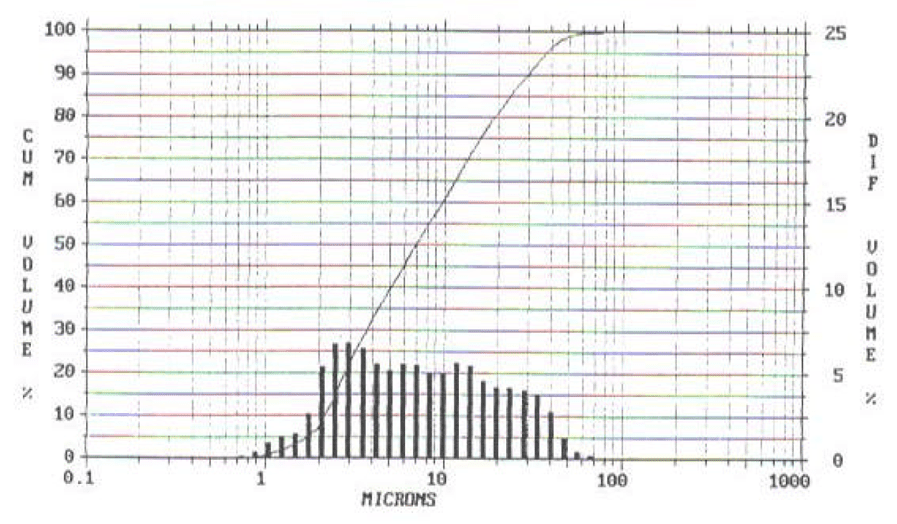

A comparison of zircon particle size and distribution is shown in Table 3.

Table 3 Zircon PSD comparisons

|

400 Mesh |

325 Mesh |

200 Mesh |

|||

|

|

|

|||

|

D10 |

2.2 µm |

D10 |

2.2 µm |

D10 |

2.4 µm |

|

D50 |

10.9 µm |

D50 |

11.2 µm |

D50 |

24.3 µm |

|

D90 |

30.6 µm |

D90 |

36.1 µm |

D90 |

65.1 µm |

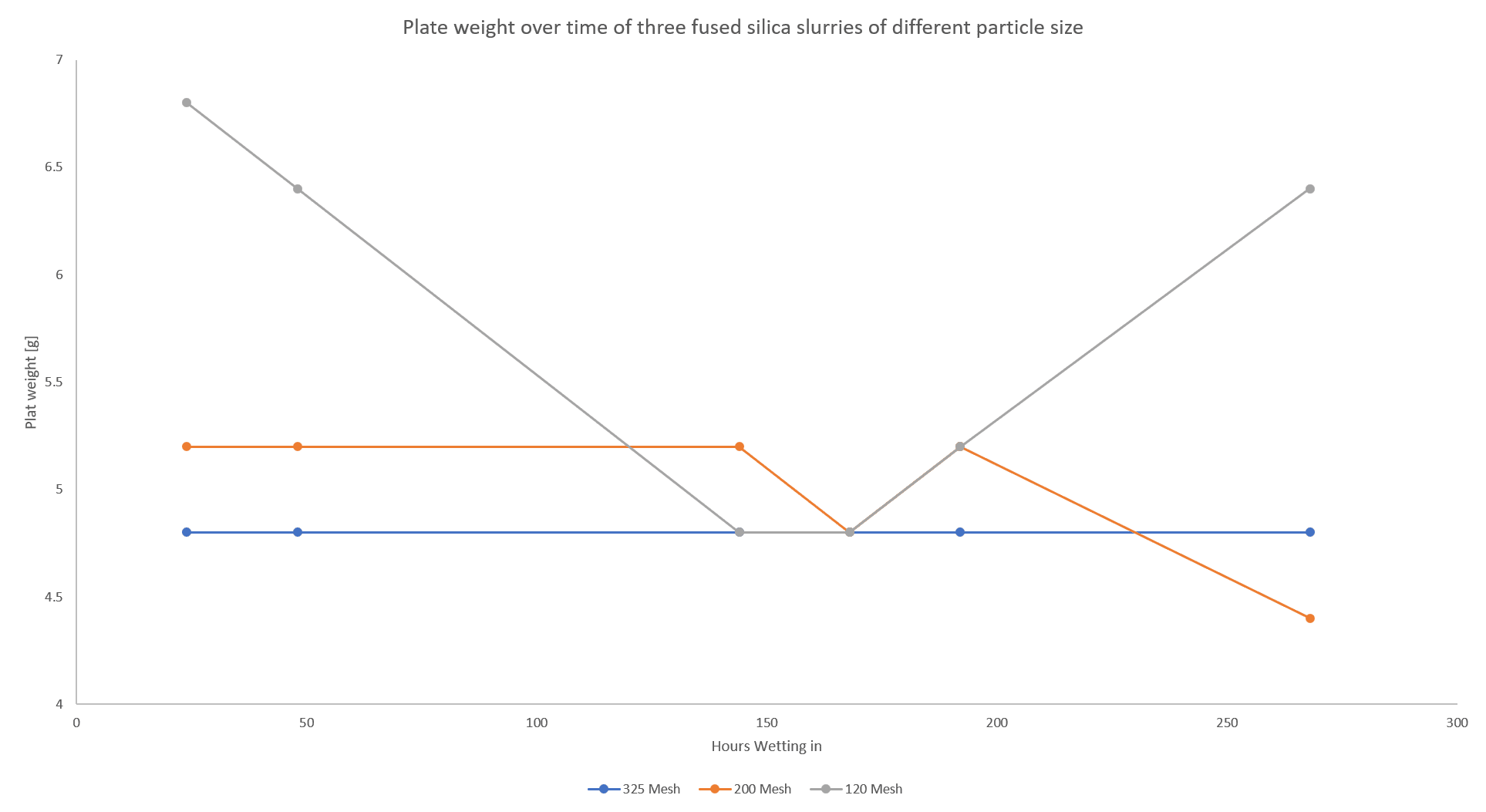

Three grinds of fused silica were prepared into slurries. The formula is shown in Table 4.

Table 4 Fused silica slurry formulation

| Material | Quantity |

| Colloidal silica | 1080 g |

| Water | 120 g |

| Surfactant | 2.5 ml |

| Antifoam | 1.5 ml |

| Fused Silica flour | 2500 g |

| Solids contents | 75-76% |

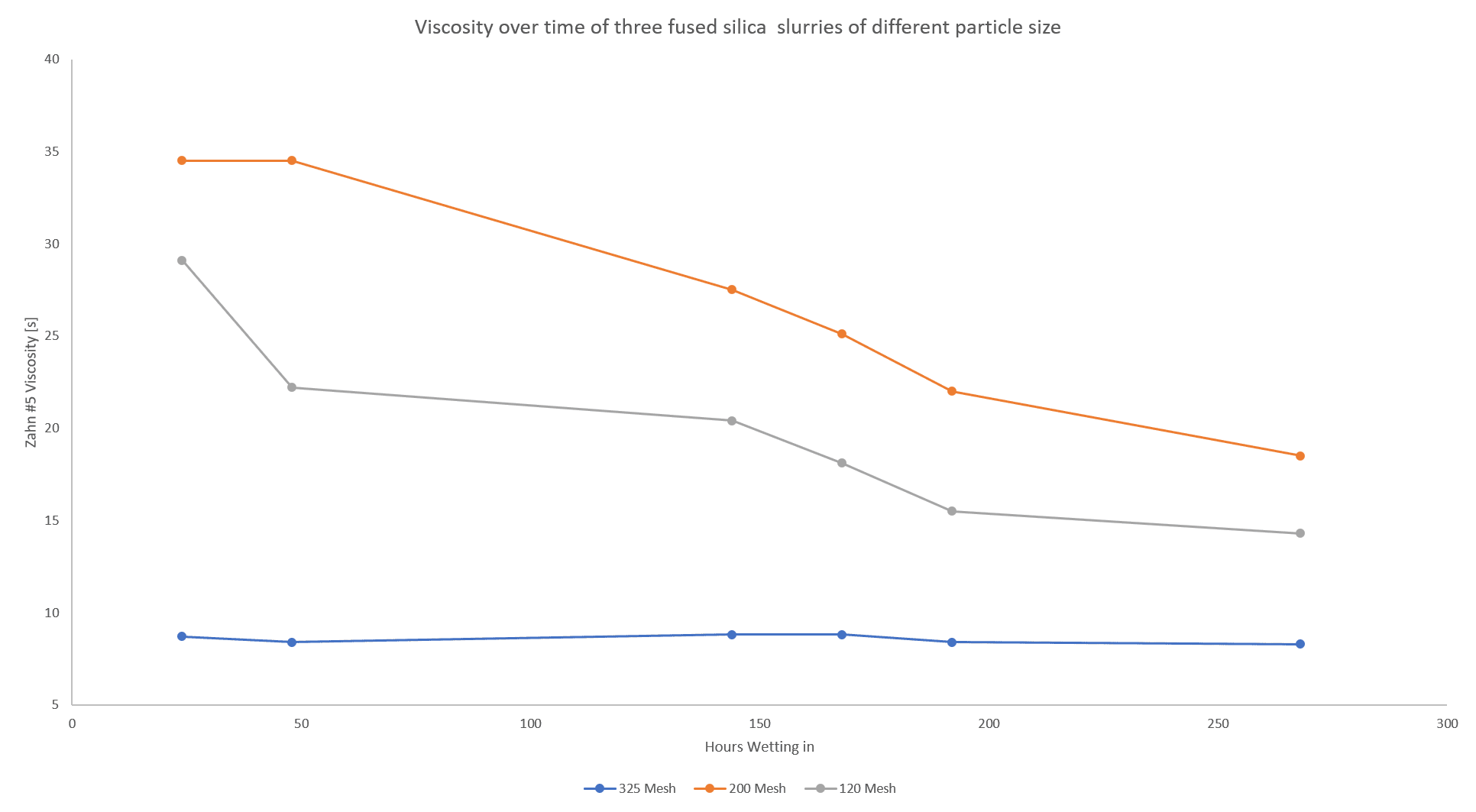

Figure 2 compares the rheological properties of these slurries. Again, note the time required to “wet” the refractories. The -325 mesh wets in almost immediately when compared to the -200 and -120 mesh material.

| Figure 2 (a) Plate weight and (b) viscosity measurements over time versus different fused silica PSD | |

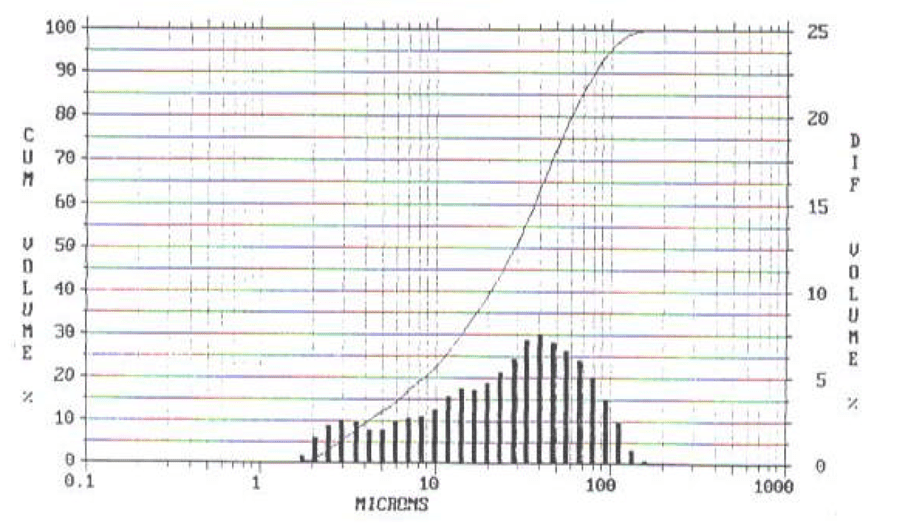

Compare the properties of slurry made from the -200 mesh material with that made from the -120 mesh product. Viscosity is higher and the plate weight is lower than the -120 mesh slurry. Now compare the -200 mesh slurry with the -325 mesh product. The plate weight compares closely, however the viscosity does not. The -325 mesh fused silica was ground by a different process. It was batch ground. The -200 and -120 mesh products were milled in a continuous process mill. Table 4 compares the particle size and distribution for -325, -200 and -120 mesh fused silica, respectively.

Table 5 Fused Silica PSD comparisons

| 325 Mesh | 200 Mesh | 120 Mesh | |||

|

|

|

|||

| D10 | 2.2 | D10 | 4.2 | D10 | 5.5 |

| D50 | 7.0 | D50 | 28.5 | D50 | 43.3 |

| D90 | 29.4 | D90 | 81.7 | D90 | 142.3 |

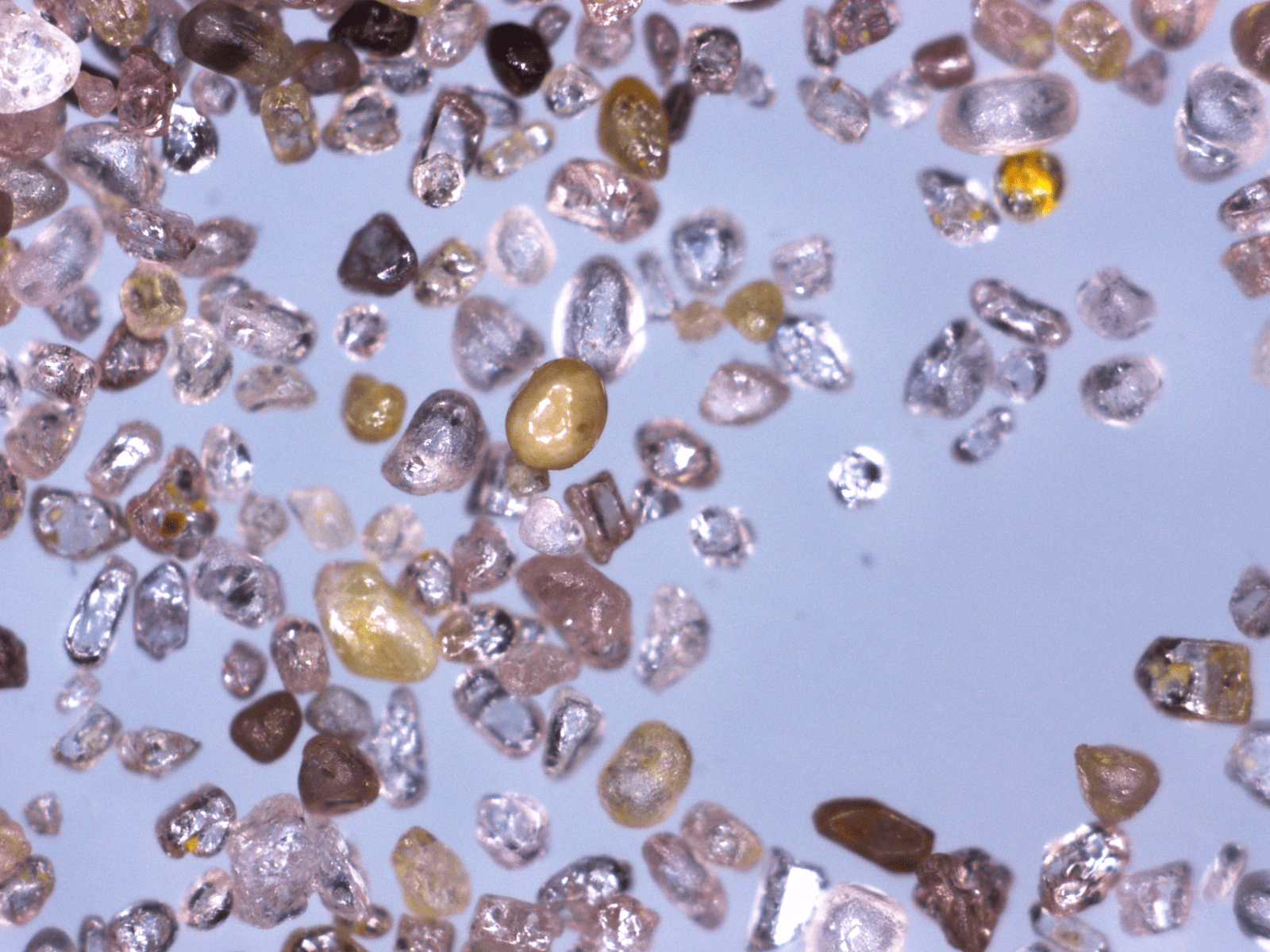

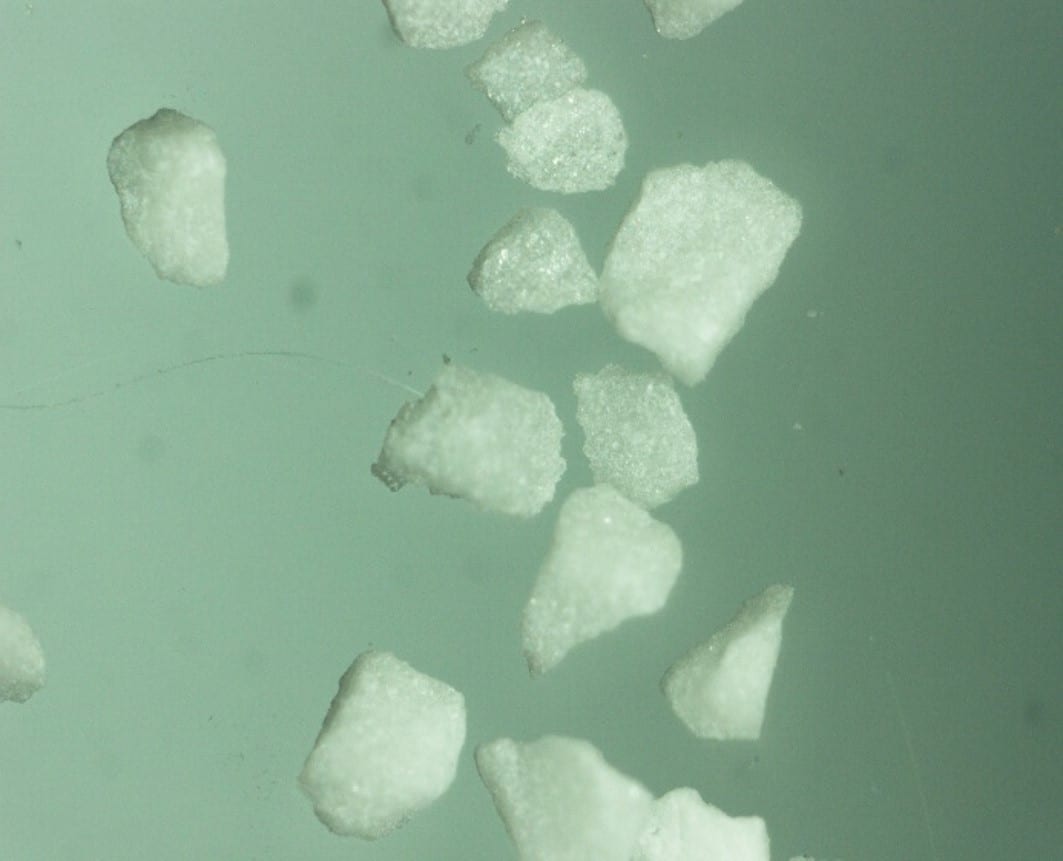

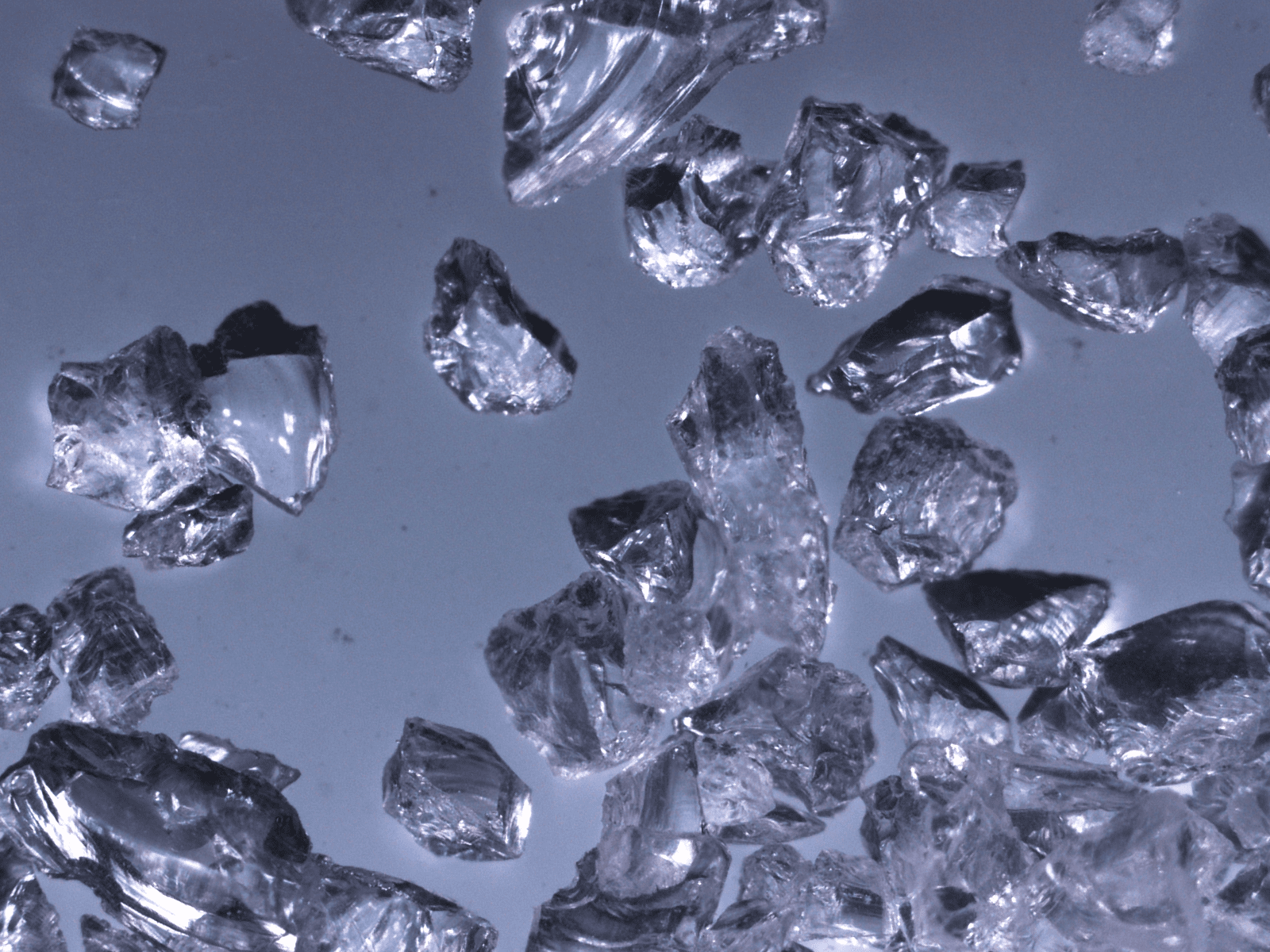

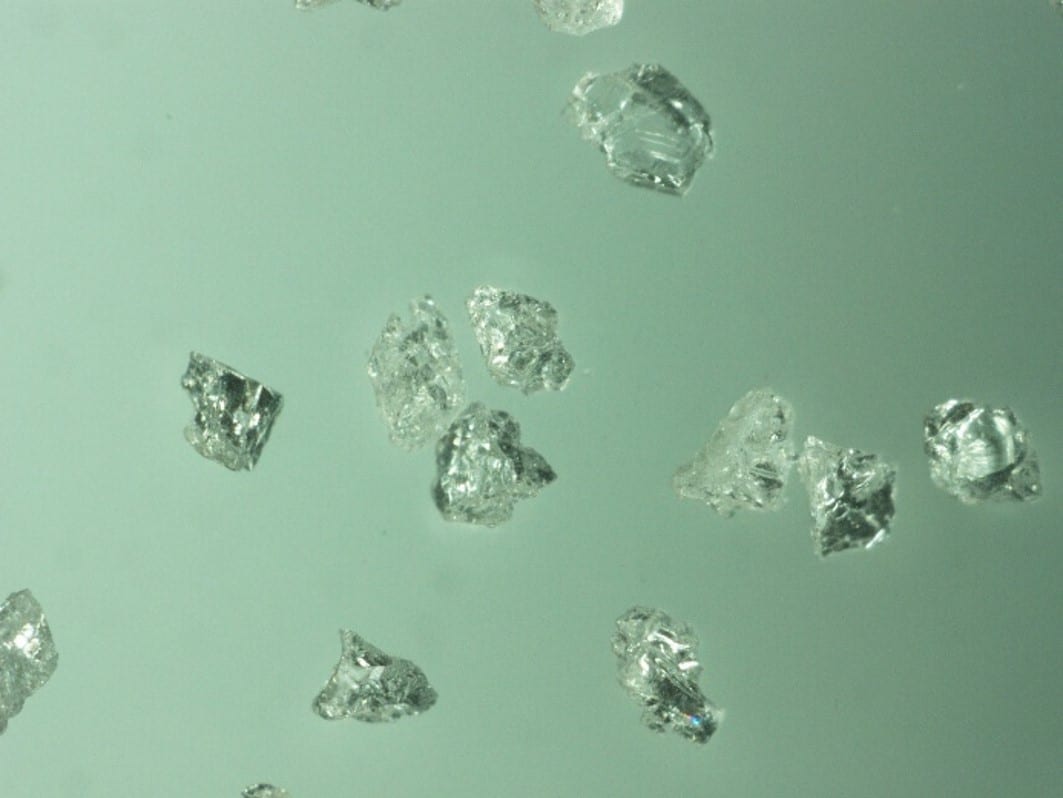

You will see that the -325 mesh flour has a narrow fairly even distribution when compared with the -200 and -120 mesh products. You will recall that I included particle size distribution as a contribution factor in rheology control. I apologize that we do not have hard data to present that shows how it affects rheology. I will describe what happens. Particle distribution affects tap density. Tap density is the maximum density of a dry refractory blend that has been vibrated or shaken to maximum compaction. There is a particle distribution blend that produces a maximum bulk density. This blend, when mixed with a small amount of binder, will produce a product with cement like consistency at rest. Vibration will make it flowable. Small amounts of binder added will greatly change its character to become more fluid like. It has a non-newtonian (thixotropic) behaviour. A change in particle distribution that reduces tap density will produce a slurry whose behaviour is more newtonian. Refractories with similar surface areas can have different particle size distribution. A particle size distribution will change slurry rheology. Refractory morphology also affects slurry rheology. Grain shape defines the surface area to volume ratio. Some refractories can also be porous. Following are SEM photos of several man made and natural minerals at 1500 x magnification. Figure 3 shows microscopy images of refractory particles. Note the rough surface and what appears to be plates. The aluminosilicate, like zircon, is a naturally mined and processed refractory. It is an aluminosilicate, containing approximately 48% Al2O3. Notice the similarity to zircon, rough surface, plate like. Tabular alumina has been calcined at temperatures that can cause some fusion. The surface shows sharp fractures and is not as rough as the zircon or aluminosilicate. Fused white alumina, is a man-made alumina. It too has sharp fractures and smooth surfaces. Fused silica has features nearly identical to fused alumina.

| Aluminosilicate | Zircon |

|

|

| Tab Alumina | |

|

|

| Fused Silica | Fused White Alumina |

|

|

Figure 3 Microscopy images of refractory particles

Conclusion

All the ingredients that make up a slurry influence how that slurry behaves and ultimately the quality of the shell. The refractory is a major contributor to rheological behaviour of the slurry. Those refractory properties that affect slurry behaviour are:

- Particle size

- Particle distribution

- Morphology

- Manufacturing process

Disclaimer

Contact your nearest REMET Sales Office regarding product specifications. Contact your REMET Territory Manager and visit www.remet.com if you have any questions or require additional information. Information and/or recommendations based on research and technical data believed to be reliable. Offered free of charge for use by persons with technical skills, at their own discretion and risk, without guarantee of accuracy REMET makes no warranties, express or implied, and assumes no liability as to the use of its products or of any information pertaining thereto. Nothing herein is intended as a recommendation to infringe any patent.

< Back to insights