How much does my shell cost?

In this short article I will show you how to calculate the true cost of a shell during production. By using a mixture of testing and weight measurements, it is very easy to measure what the true cost and use of materials for a shell system is. Given a shell system can be made of up to 10-15 different materials of varying costs, it can be difficult to understand what your true cost of a shell is, compared to a standard wax pattern or metal part. This article will step through a method to understand the constituent materials within the shell system per coat.

Firstly, we need to understand what the constituents are of a slurry. As we know, assuming a slurry is the same as the recipe at a given time is not an accurate approach due issues with evaporation, settling etc. This can be estimated accurately, by carrying out the following tests on a slurry:

- % Total Solids

- % Slurry solids

- % Polymer

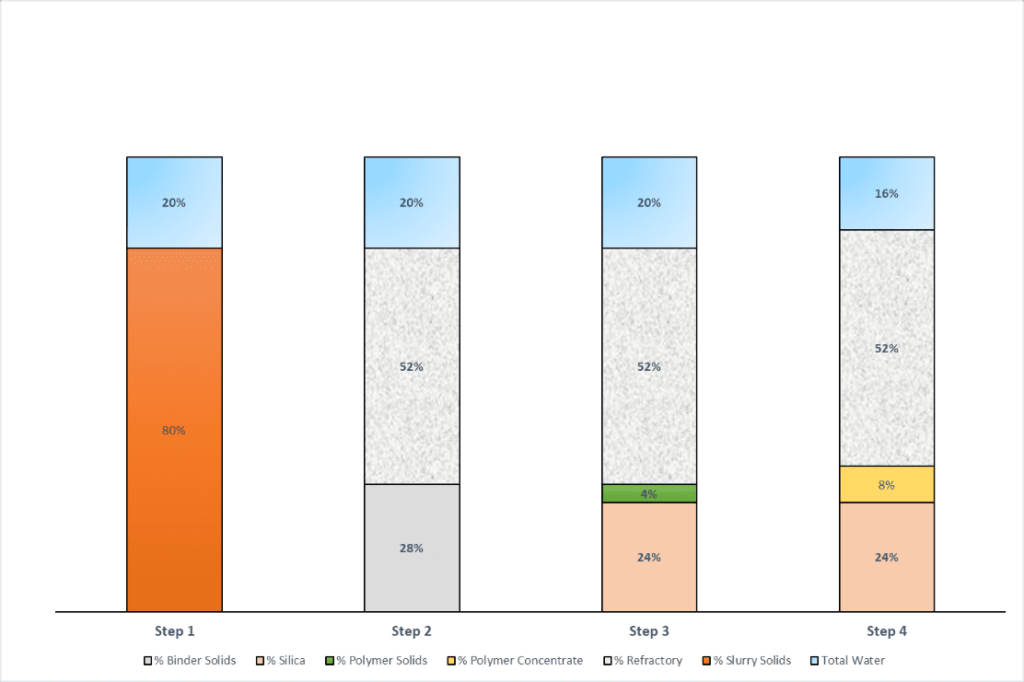

With these three values, we can deduce what is in the slurry as per the figure below.

- Step one is to assess the total solids content. This is the sum of the refractory, silica and polymer solids within the slurry. This value gives us the % solids and also the % water (which we will use later).

- Step Two – By assessing the % binder solids test, we know what percent of the total solids can be attributed to the binder solids (polymer and silica) and the refractory.

- Step Three, if we carry out the % silica test, we can assess the total % silica and by subtraction, the % polymer within the system.

- Finally, the % polymer concentrate is typically 50:50 solids and water, therefore if we double the % polymer solids value, we arrive at step 4, the full breakdown of our shell system.

Unfortunately, there is no analytical method to assess the total concentration of antifoam and wetting agent within a slurry, so this can be either ignored as negligible within the slurry or estimated from the original formula.

Okay, so we have what the slurry is made up of, now where do we go? Well, during the standard dipping of the shell, we can estimate the other costs of material. Below are the steps to carry out the analysis.

- Step 1 – If we calculate the wet weight of a shell after dipping and sanding, this will be the total weight of slurry (including water, binder and stucco).

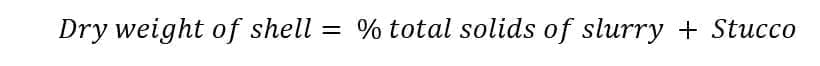

- Step 2 – If we leave this to completely dry, 100% water loss is achieved, we get the total solids of the shell. This will be a combination of slurry solids and stucco:

- Step 3 – By subtraction, we know how much water is lost, we can work backwards with the earlier % total solids calculation to calculate what the original weight of slurry within the shell.

- Finally, once we know all these values, we can subtract the total wet weight by the weight of slurry to find the stucco pickup.

This will give us an accurate picture of all components in the slurry. It takes some simple arithmetic and a little bit of thinking, but it is a very good way of assessing the constituent materials and final cost of a part.

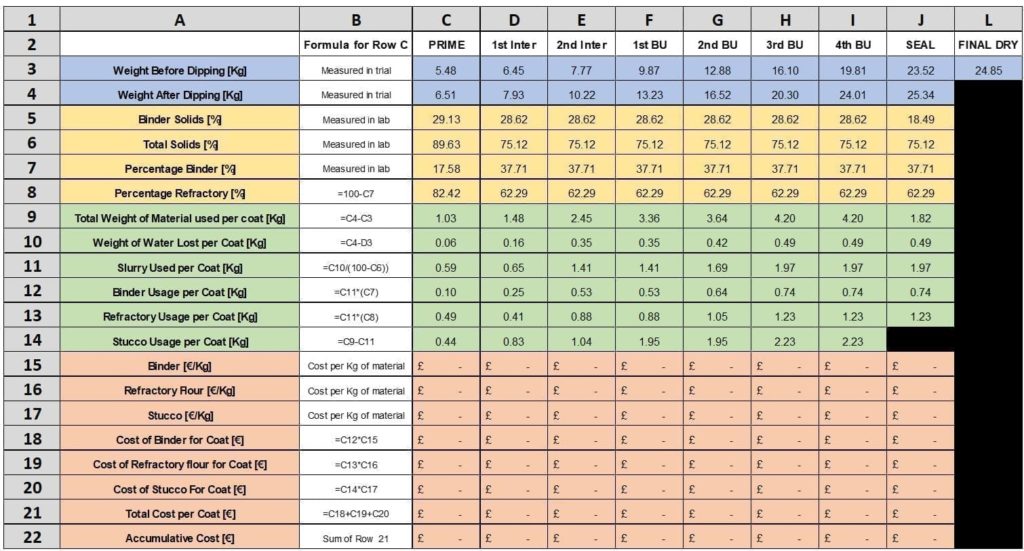

Worked Example

Below is an example in practice of how the above equations can be used to calculate the cost of your shell. The shell system under review had one prime, 2 intermediates and a subsequent 4 backup coats. The same slurry was used for intermediate and backup coats. The formulas for row C are also included. Costs are eliminated as these depend on the material you are using.

By using this data, graphs like below can be used to assess where the cost of material are within the shell building process. Of course, savings in dry time/build rates etc. can be better calculated by using this method within a project also. Models for labour, environmental conditions and labour can also be added to the calculation.

For more information about how REMET can reduce costs across your whole process contact your REMET representative or visit our website.

< Back to insights